Armoloy Coating

The Armoloy coating is specifically designed to keep tooling running efficiently and lasting longer. For increased wear life, reduced friction, and protection from corrosion the coating increases cycle times, decreases waste and improves performance.

A guideline for Armoloy TDC Success – As the surface hardness and surface finish of your basis metals improves, the performance of the Armoloy TDC coating also improves. Armoloy is a Cold process – Armoloy TDC is applied at 135°F and short run times. This means no distortion or molecular change to the part. Armoloy’s TDC unique processing and preprocess surface preparation minimizes parts’ overall exposure to hydrogen – which decreases the chance of hydrogen embrittlement. (Original conditions may not be removed).

Wherever Armoloy-to-Armoloy coated parts contact each other, these characteristics are further enhanced for even less friction, longer life and corrosion resistance.

Resources

The Electrolizing Thin, Dense, Chromium Process (PDF)

Why The Greatest Tool Is Not In Your Toolbox (PDF)

Video: Armoloy won't chip, crack, or peel

Wear-resistant hardness

Double Race Bearing

Key advantages:

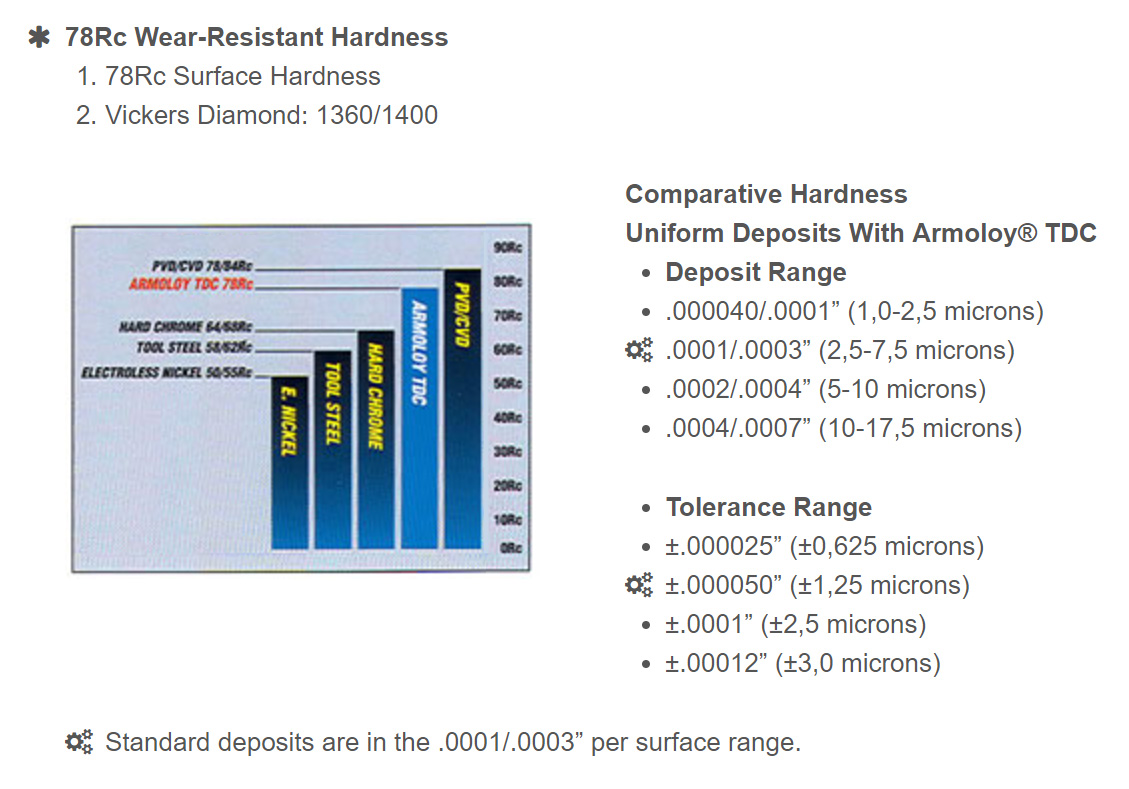

- High hardness – at 78Rc, Armoloy thin dense chrome is one of the hardest coatings available.

- Nodularity – A key property of Armoloy is a nodular effect which increases lubricant retention and reduces surface contact area. This in turn improves the wear life and reduces friction.

- Absolute adhesion – Armoloy coating will not chip, flake, crack, peel, or separate from the base metal under standard ASTM ben tests or under conditions of extreme heat or cold.

- Uniform deposits – without thickness or edge build-up or “dog-boning” associated with conventional chrome plating processes. No requirement for post finishing (except special applications)

- Typical thickness – the standard deposit thickness of Armoloy TDC ranges between 0.0001”-0.0003” with a tolerance range of +/- of 0.000050”.

- Surface finish – RMS finishes will improve slightly to ✓8 (below ✓8 the process may deter slightly.) Surfaces greater than ✓62 will reflect greatly improved finishes.

- Anti-Galling – Armoloy is an excellent solution to galling issues. Many customers have shared stories of how Armoloy eliminated or greatly reduced their galling issues!

- Improved wear protection – With improved hardness and lubricity your parts will wear better and last longer.

- Improved corrosion resistance – Armoloy resists attack by most organic and inorganic compounds, with the exception of sulfuric acid and hydrochloric acid. Of course, base metal porosity, surface hardness and other imperfections affect basic corrosion-resistant properties. All basis metals with the Armoloy coating are enhanced. Conforms to ASTM-B117 and others.

- Improved appearance – Employed as the finishing step for machine parts and manufacturing components, Armoloy imparts a satiny, silver matte, micro-nodular finish.

- Molding areas stay cleaner longer – and require less maintenance while burnt on plastic and rubber can be quickly removed.