Food Processing Case Study

Armoloy is a metal treatment that increases hardness and corrosive tolerance. It works by penetrating the metal surface with a chromium coating while adding minimal thickness to the treated metal. It is USDA approved for food use, and increases metal hardness to approx 78Rc. It will not peel, crack, or flake due to the deep penetration. It is more of a metal infusion than a coating. Low temperature application reduces metal distortion. It can be stripped and reapplied without affecting base metal.

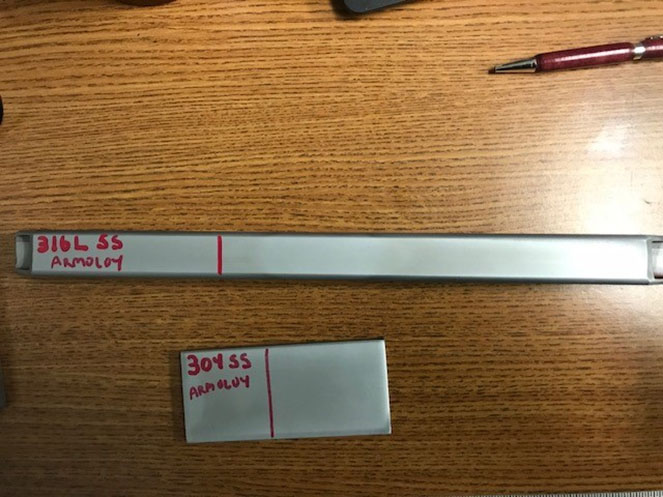

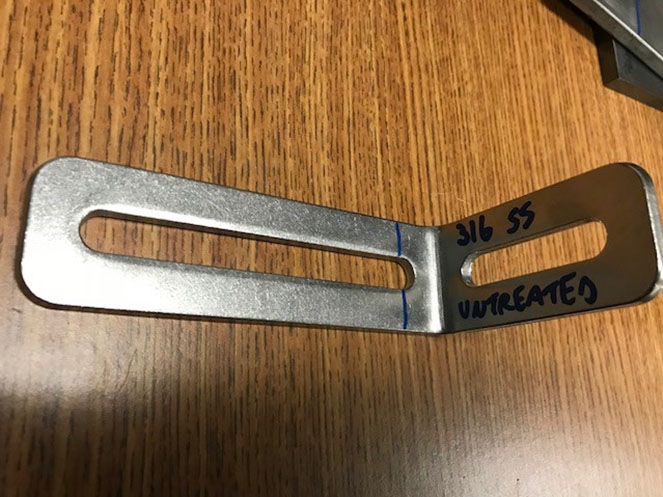

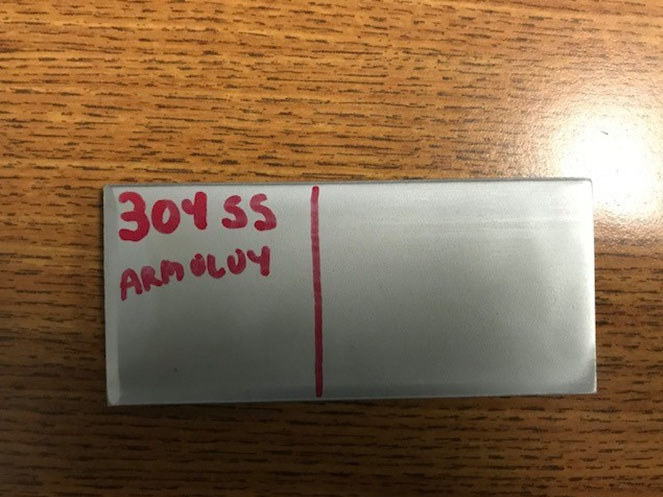

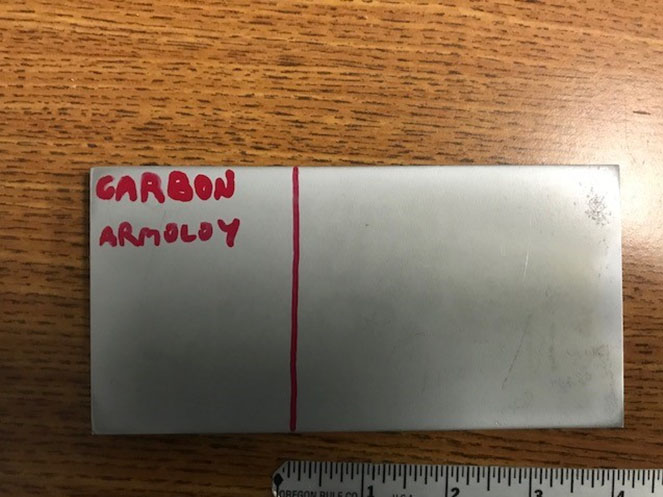

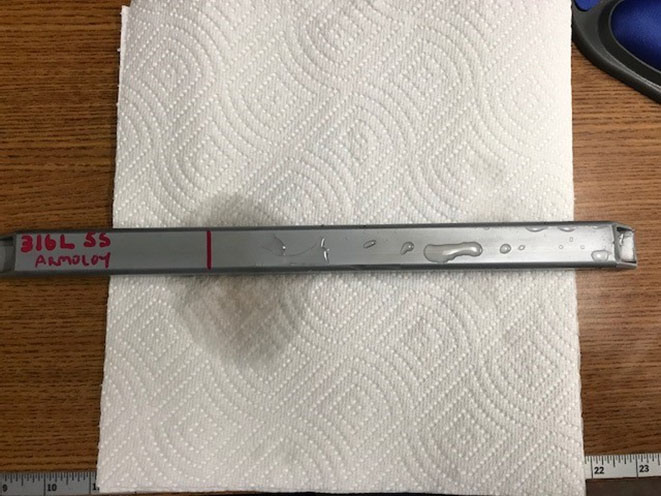

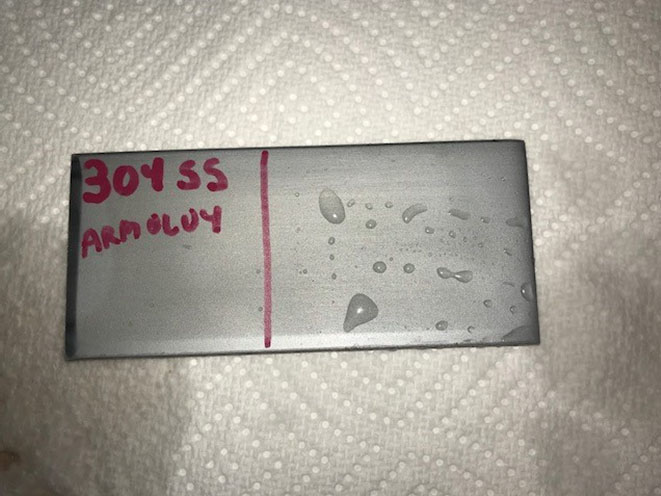

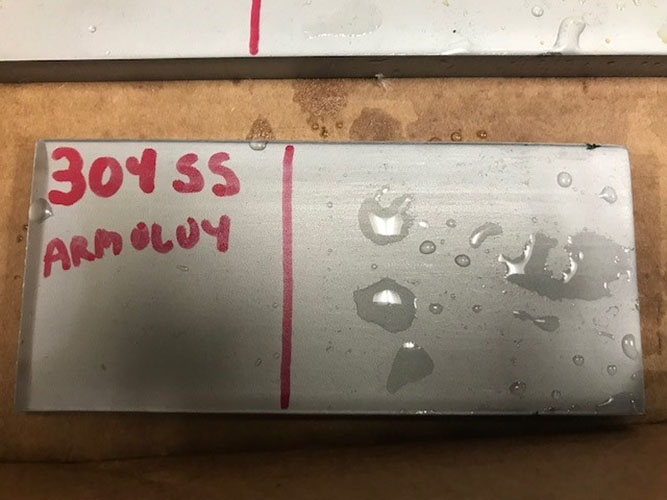

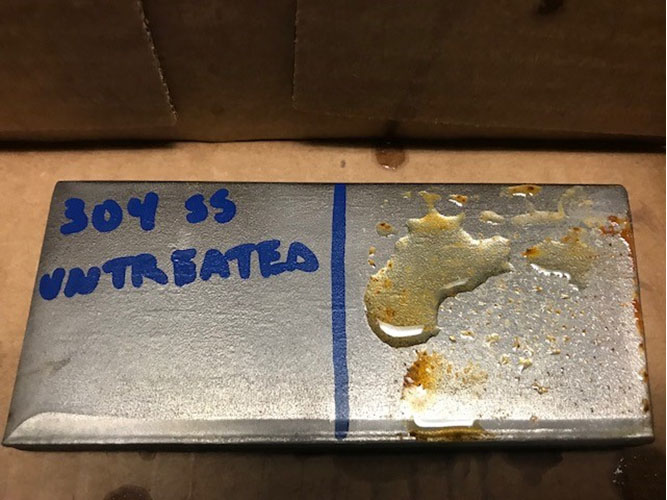

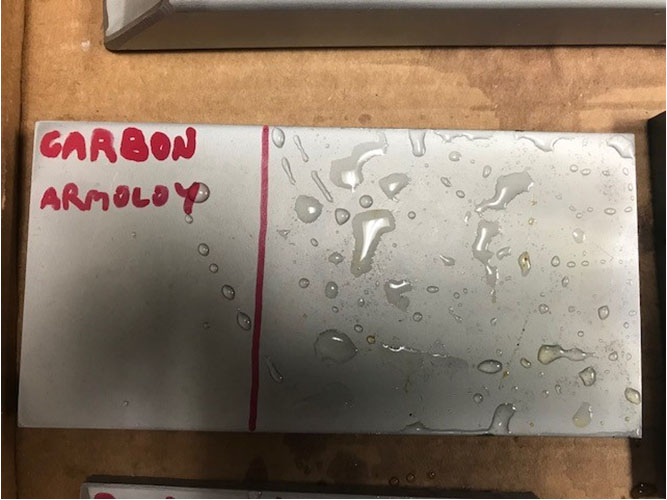

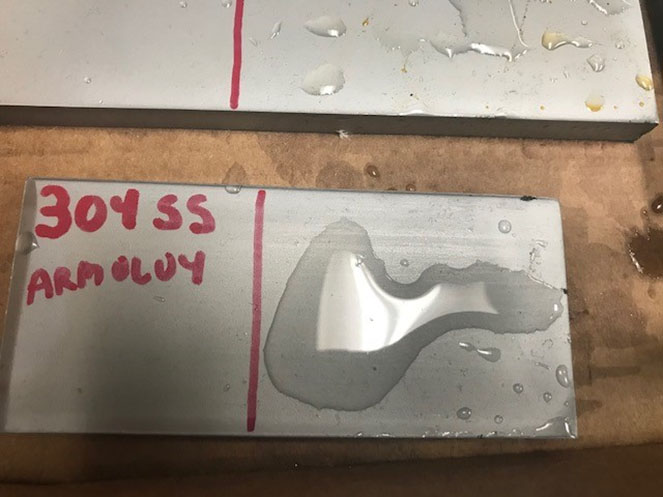

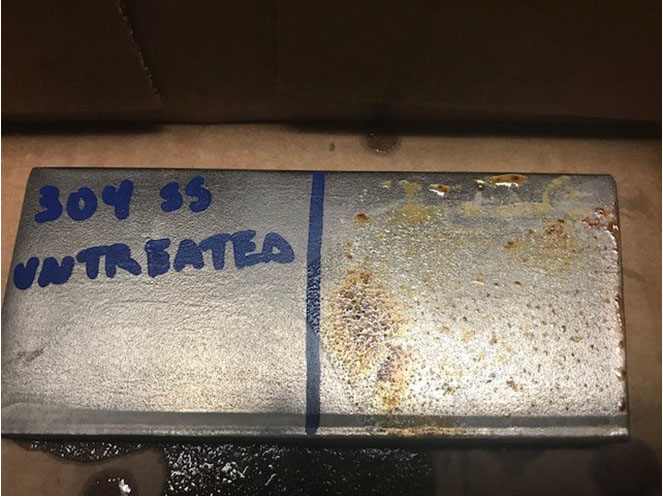

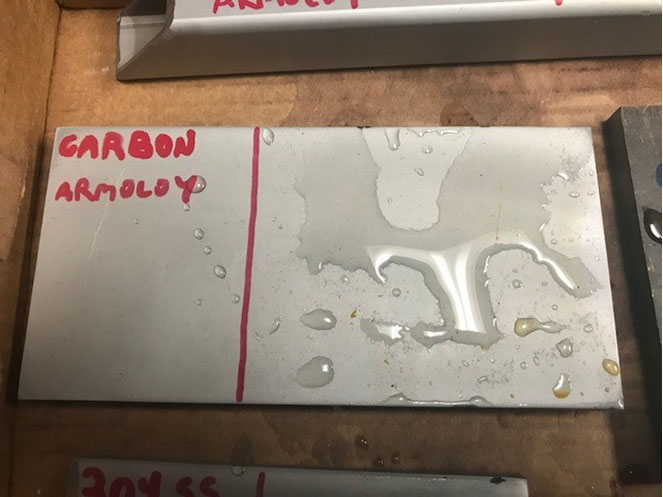

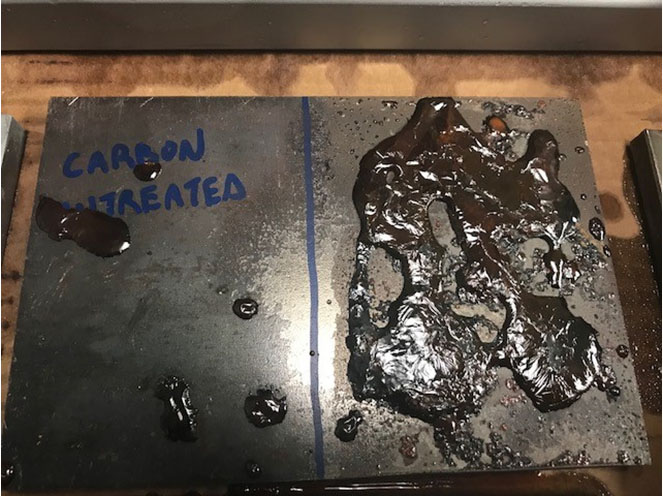

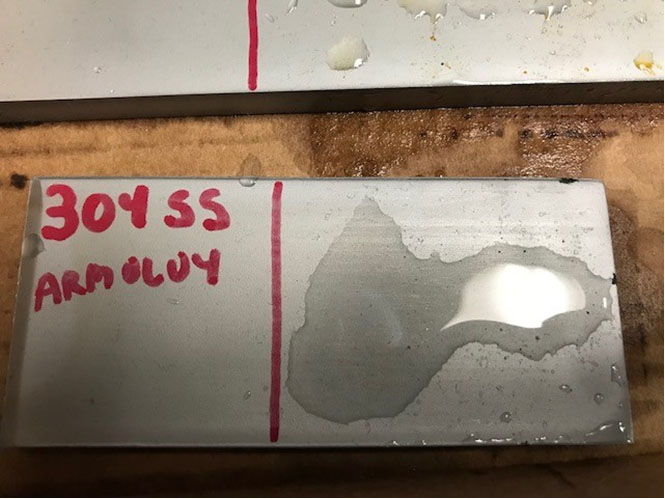

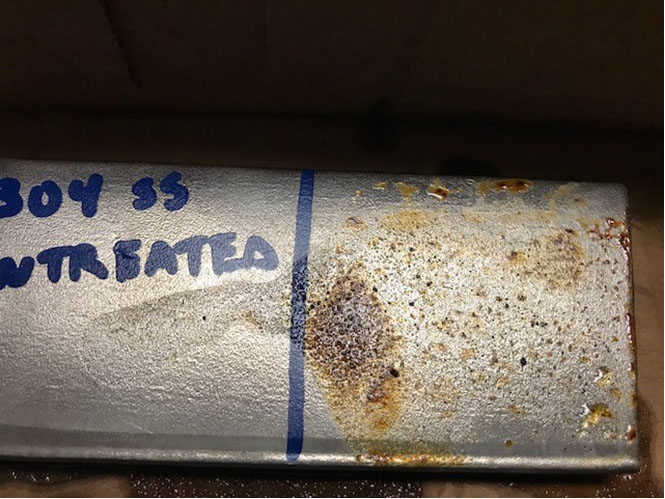

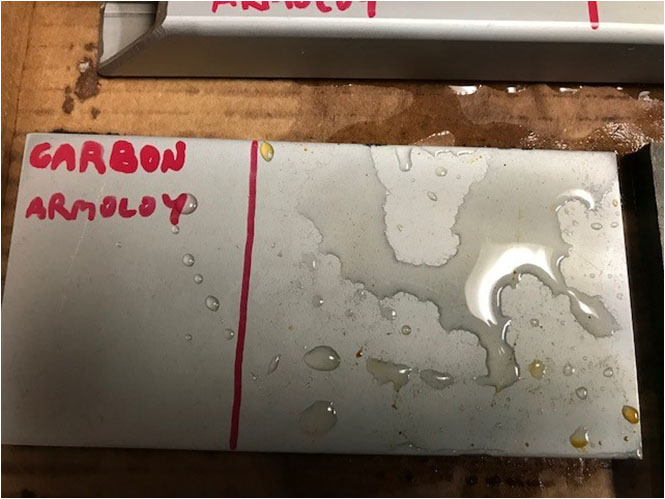

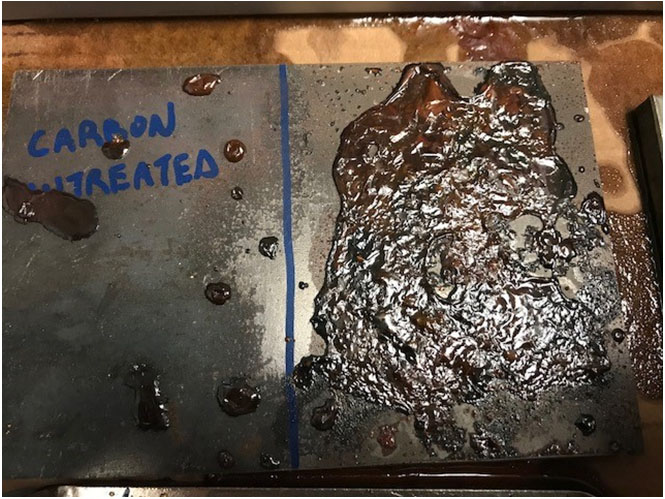

This test consisted of 3 treated and 3 untreated metal samples. One treated and untreated each of 316L SS, 304L SS, and carbon steel. Each sample piece was introduced to a brine solution by method of dripping once per week for five weeks. Observations and pictures are below.

The purpose of this test was to monitor corrosion against untreated samples to determine treatment effectiveness for use on brine contact surfaces within our plant.

Study Timeline

Day 1 |

6/28/2018 | Initial exposure to brine solution for all sample pieces. |

Day 7 |

7/4/2018 | Armoloy treated samples showing little to no sign of corrosion. Carbon treated sample showing a discolored drip which could be surface metal dust but now metal intrusion 316 and 304 treated samples shows no signs of corrosion. All Armoloy samples showing some sign of oxidation Carbon Armoloy sample, as expected, showing surface corrosion and signs of metal intrusion. 304 Armoloy sample has surface oxidation and minimal signs of metal corrosion 316 Armoloy sample only shows surface oxidation at this point. |

Day 14 |

7/11/2018 | 316SS and 304SS treated samples showing no signs of corrosion. Minimal surface oxidation on the carbon treated sample. 304SS and 316SS Armoloy samples showing some surface corrosion with very minimal deteriation. Carbon Armoloy sample with corrosion and metal flaking/pitting. |

Day 21 |

7/18/2018 | SS treated samples showing no signs of corrosion with the carbon treated sample showing minimal surface oxidation Armoloy samples with expected corrosion continuation with 304 ss showing deeper signs of corrosion. 316SS shows continues surface oxidation with minimal intrusion. |

Day 28 |

7/25/2018 | Treated samples continue to be resistant to brine corrosion with only minimal surface oxidation on carbon sample. Armoloy samples with further continuation of corrosion as seen in previous observations. |

Conclusion

It is safe to conclude at this point that this treatment would greatly increase corrosion resistance to our base metals for any parts/frames within contact of our brine solution.