Resources

Better Performance with Chromium Coatings and Industrial Lubricants

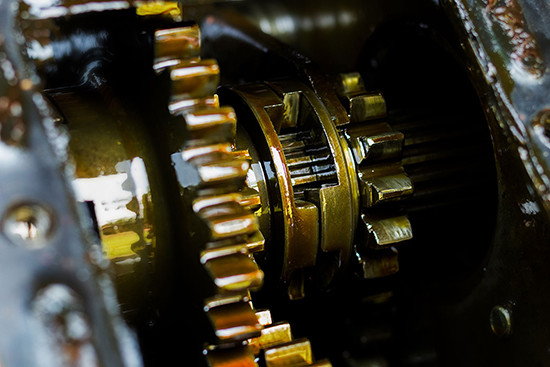

The combination of lubricants and chromium coatings plays a pivotal role in enhancing the performance and longevity of machinery. The type of lubricants used and how systems incorporate it vary based on the kind of device, the operating environment, and other factors. Their effectiveness is significantly amplified when used in conjunction with chromium coatings.

Read More

Diagnosing Metal Degradation: Erosion Vs. Corrosion

Understanding the forces of erosion and corrosion is essential for anyone involved with metal components, as both threaten metal integrity. Read the full article for more information on spotting signs, understanding high-risk zones, and, most importantly, how Armoloy of Ohio’s solutions can protect your metal products.

Read More

EVER WONDERED HOW THE ELECTROPHORETIC DEPOSITION COATING PROCESS WORKS?

Simple Solutions That Work! - April 2019

Read More

PDF Download (2.9 KB)

Injection Molding

With Armoloy Thin Dense Chrome we see less flashing issues as well. Armoloy TDC creates a 78Rc surface hardness. This helps maintain the design of the mold and drastically slows down the degradation process. Less degrading means less flashing.

Read More

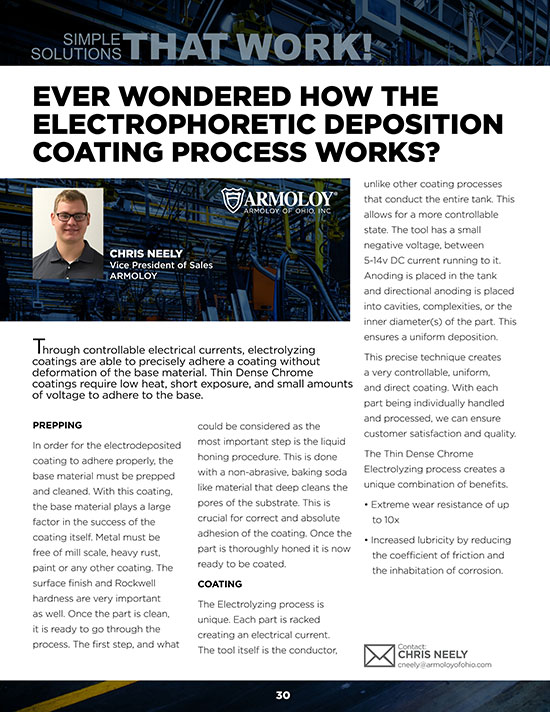

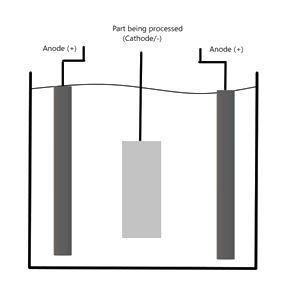

Ever Wondered How The Electrophoretic Deposition Coating Process Works?

Through controllable electrical currents, electrolyzing coatings are able to precisely adhere a coating without deformation of the base material. Thin Dense Chrome coatings require low heat, short exposure, and small amounts of voltage to adhere to the base.

Read More

A SIMPLE cOATING sOLUTION

Simple Solutions That Work! - September 2018

Read More

PDF Download (1.5 KB)

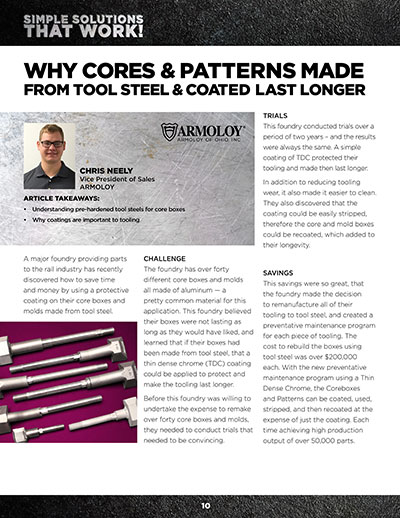

WHY CORES & PATTERNS MADE FROM TOOL STEEL & COATED LAST LONGER, by Chris Neely

Simple Solutions That Work! - April 2018

PDF Download (2.40 MB)

Creating Efficient Tooling for Your Foundry, by Chris Neely

Foundry Management & Technology, January 2018

Reprinted with permission of Penton Media

Article

Why the Greatest Tool is Not in Your Toolbox, by Chris Neely

Simple Solutions That Work! - September 2017

PDF Download (267 kb)

Whitepaper: The Electrolizing Thin, Dense, Chromium Process

PDF Download (178 kb)

UDSA Equipment Acceptance Certificate

PDF Download (2.8 Mb)

Armoloy Brochure

PDF Download (2.5 Mb)