Safe and Efficient

Operations with TDC

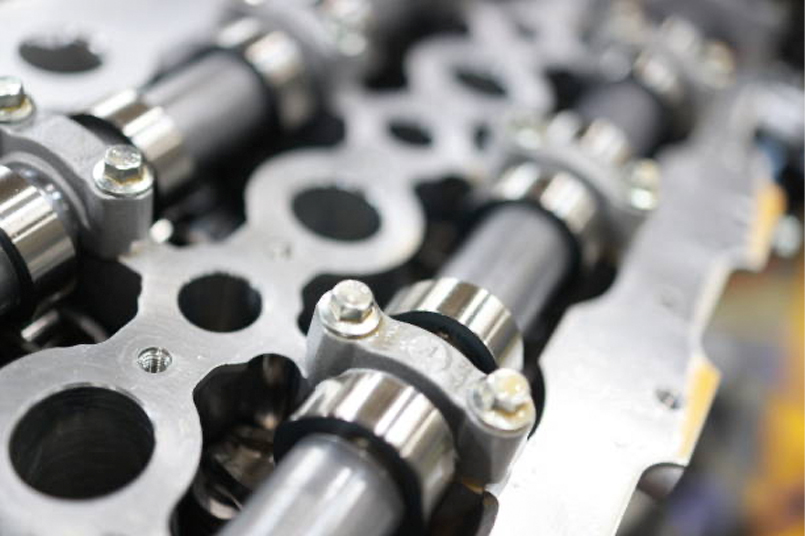

Reducing friction, wear, and corrosion, Armoloy of Ohio's TDC® (Thin Dense Chrome) extends the lifespan of critical components and lowers maintenance risks.

Friction Reduction

Friction in machinery causes wear and tear, leading to maintenance and safety issues. Armoloy's TDC coating is a low-friction barrier, allowing components to operate with minimal resistance and heat generation.

Heat Resistant

TDC coatings stay stable at elevated temperatures, reducing the risk of thermal degradation or failure in high-heat applications.

Wear Resistance

TDC coatings offer exceptional hardness and durability, maintaining component integrity. They ensure performance over time, with up to 78Rc hardness, minimizing wear.

Corrosion Protection

Corrosion threatens components' structural integrity, causing safety risks and costly repairs. Armoloy's TDC acts as a barrier, providing corrosion resistance equivalent to 440C stainless steel. It shields components from moisture, chemicals, or other corrosive agents.

Reduced Maintenance for Safer Operations

TDC reduces maintenance interventions by extending component life and minimizing wear and corrosion. This results in reduced costs and hazards associated with equipment disassembly, repair, and reassembly.

With Armoloy of Ohio, expect a 99%+ customer satisfaction rating and fast turnaround times. Reduce risk and prioritize safety with superior metal protection.