Case Studies

High Precision Rollers Last 3x Longer with Armoloy TDC

When Armoloy TDC is applied to a base material it provides three significant advantages:

- Surface hardness 78Rc

- Lubricity is increased by reducing the coefficient of friction 25 – 50%

- Corrosion is reduced

Armoloy is only as good the base material that it is adhered to. Better base materials provide for even better results. For example, if you are using a treated tool steel that is reaching +62Rc—what can you expect? That is where the added lubricity can really stand out, as creating less friction reduces wear. Tool steels tend to be expensive, therefore, reducing wear on high strength tool steels can result in substantial cost savings.

Why Base Material Matters

The foundation of your house is critical to the structure and integrity of your house. Much like foundation, base material is crucial to the integrity and strength of your tool. Choosing the right base material will provide the longest lasting tool or mold. Your base material plays a major role in the strength, surface finish, corrosion resistance, and machinability of your tool or mold.

Though strength and heat treating are major benefits for coating your parts; Armoloy TDC is not a replacement for heat treating as it does not affect the underlying base material—just surface hardness. We like to use the metaphor; it’s like putting glass over a marshmallow. If the tool is put under immense amount of pressure, the base material will give. If you have a nice foundation it will remain sturdy during the process. On the other end, if a part is designed to be sacrificial to prevent a catastrophic failure, then the part is going to remain sacrificial and the normal wear and tear is going to significantly increase.

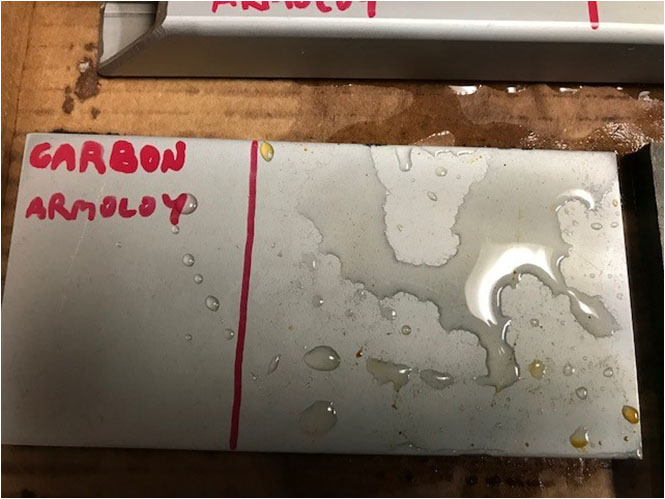

Food Processing Case Study

This test consisted of 3 treated and 3 untreated metal samples. One treated and untreated each of 316L SS, 304L SS, and carbon steel. Each sample piece was introduced to a brine solution by method of dripping once per week for five weeks. Observations and pictures are below.

The purpose of this test was to monitor corrosion against untreated samples to determine treatment effectiveness for use on brine contact surfaces within our plant.